To maximize the performance of an engine, several methods can be employed. These range from modifying the air-fuel ratio and spark timing to upgrading components such as the intake manifold and exhaust system. Additionally, factors like lubrication, cooling, and servicing play a significant role in maintaining optimal engine functionality.

- Continuously inspecting the engine for any malfunctions can help mitigate potential performance reduction.

- Employing high-quality fuel and lubricants can improve engine performance.

- Implementing cutting-edge engine management systems can offer precise control over various engine parameters, leading to improved efficiency and performance.

Transmission Fluid Maintenance

Proper transmission fluid maintenance is crucial for guaranteeing the longevity and performance of your vehicle's transmission system. Like any fluid, transmission fluid deteriorates over time, losing its ability to effectively regulate temperature. This can result premature wear on mechanical within the transmission.

Regular changing out your transmission fluid is a key procedure in prolonging its lifespan. Consult your owner's manual for suggested intervals for this important maintenance task.

It's also important to monitor the status of your transmission fluid regularly. A healthy transmission fluid should be a vibrant red and without any signs of wear and tear. If you notice any problems, it's crucial to minimize further damage.

Ultimately, proactive transmission fluid maintenance can save costly repairs down the road and help ensure your vehicle operates smoothly for years to come.

Fundamental Aspects of Frame Design

When designing frames, ensuring sturdiness is paramount. This necessitates careful evaluation of various parameters that affect the integrity of the frame. Shape plays a fundamental role, with sizes directly determining the resistance to withstand forces. The choice of elements is equally important, as different materials possess varying toughness. Connections must be reliable to minimize failure points.

- Furthermore, environmental factors such as temperature, dampness, and corrosion can impact the performance of the frame over time.

- {Therefore|{Consequently|Thus|, it is imperative to incorporate these design into every stage of the development process to guarantee a safe and dependable structure.

Suspension Fork Geometry and Its Impact on Handling

When it comes to mountain biking, suspension fork geometry is critical for a smooth and predictable ride. The angle of the fork, along with its offset, directly influence how your bike handles in different situations. A steeper angle generally provides higher steering precision at high speeds, while a slacker angle allows for easier cornering at lower speeds. The offset of the fork, measured from the axle, affects the stance of the bike, which determines how stable it feels when riding straight or turning.

By understanding these fundamental principles and adjusting your suspension fork geometry accordingly, you can tailor your bike's handling characteristics to suit your riding style. Whether you prioritize speed, stability, or maneuverability, fine-tuning Yamaha your suspension fork geometry is a crucial step in maximizing your riding experience.

The Evolution of Torque Distribution in Vehicles

Modern car transmissions are increasingly integrating sophisticated methods like torque vectoring to enhance handling. These systems actively distribute power between the axle during cornering, braking, and other maneuvers. By selectively redistributing torque, torque vectoring optimizes traction, stability, and grip. This results in a more dynamic driving experience with eliminated understeer or oversteer.

- Additionally, torque vectoring can augment fuel efficiency by regulating power delivery to individual wheels, maximizing traction and minimizing energy waste.

- Therefore, the integration of torque vectoring systems in modern transmissions represents a significant improvement in automotive technology, enabling vehicles to handle with greater precision and efficiency.

Welding Techniques for High-Strength Frame Fabrication

Fabricating strong/sturdy/robust frames necessitates precise welding/joining/fusion techniques to ensure optimal strength/durability/integrity. A variety of methods are employed, including Gas Tungsten Arc Welding (GTAW)/Shielded Metal Arc Welding (SMAW)/Flux-Cored Arc Welding (FCAW), each offering unique advantages/benefits/characteristics for specific applications. GTAW, also known as TIG welding, excels in producing high-quality/precision/cleanliness welds on thin materials. SMAW, or stick welding, is a versatile process suitable for thick plates and outdoors due to its portability/versatility/simplicity. FCAW, utilizing a continuously fed flux-cored wire, provides fast/efficient/rapid welding speeds for thicker sections. The choice of technique/process/method depends on factors such as material thickness, joint design, required weld strength, and environmental conditions. Proper preheating, filler material selection, and post-weld heat treatment are critical for achieving satisfactory/ideal/optimal results in high-strength frame fabrication.

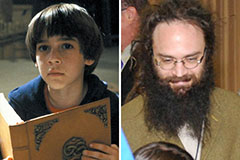

Barret Oliver Then & Now!

Barret Oliver Then & Now! Kirk Cameron Then & Now!

Kirk Cameron Then & Now! Sam Woods Then & Now!

Sam Woods Then & Now! Pauley Perrette Then & Now!

Pauley Perrette Then & Now! Ryan Phillippe Then & Now!

Ryan Phillippe Then & Now!